Study on the Efficiency and Quality of NC Carving of Jadeite——Take Sitting Maitreya Buddha Carving as An Example

-

摘要: 数控玉石雕刻技术能够降低玉石雕刻行业人力成本,提高生产效率,完成产业升级。本文选取坐式弥勒佛为例,运用JDPaint5.50设置不同参数,加工了13件质地近似的翡翠,测试了平头刀开轮廓、锥形球头刀粗刀工序和细刀工序中的加工效果、刀具损耗程度和耗时之间的关系。结果显示:速率一致时, 使用平头刀开轮廓的耗时与加工深度正相关,耗时(s)为142.27×加工深度(mm)。加工翡翠粗刀工序采用0.6 mm锥形球头刀时,安全的最大路径间距为0.08 mm,速率为25%。粗刀和细刀工序的耗时与路径间距及速率均有关系,耗时减少的幅度随着路径间距和速率的增加都越来越少。翡翠数控雕刻的表面质量主要与细刀工序的锥形球头刀刀头直径和路径间距有关,与速率大小无关。若粗刀工序路径间距较大,应通过增加粗刀工序加工余量让细刀工序去除刀路痕迹。Abstract: CNC jade carving technology can reduce the labor cost of jade carving industry, improve production efficiency and upgrade the industry. Taking sitting Maitreya buddha as an example, in this paper, the authors use JDPaint5.50 to set different parameters to carve 13 pieces of jadeite with similar texture, and test the relationship between the processing quality, the degree of tool loss and the time-consuming by different tools. The results show that: when the speed is the same, the time consumption of using the flat head cutter for shaping is positively related to the depth, and the time consumption (s) is 142.27 ×depth (mm). When 0.6 mm tapered ball-end cutter is used in the rough jade cutter processing procedure, the maximum safe path space is 0.08 mm, and the percentage of speed is 25%. The time consumption of rough and fine cutting operations is related to the path space and the percentage of speed, and the extent of time consumption reduction decreases with the increase of path space and the percentage of speed. The surface quality of CNC jade carving is mainly related to the taper ball-end cutter head diameter and path space of the fine cutting process, and is independent of the percentage of speed. If the path space of rough cutting process is large, the machining allowance of rough cutting process should be increased to allow the fine cutting process to remove the trace of tool path.

-

Keywords:

- NC machining /

- jade carving /

- path spacing /

- rate

-

玉石雕刻从8000多年前的新石器时代开始就是我国重要的加工技艺之一。随着技术不断进步,数控加工技术已经深入玉石雕刻行业。李敏芳[1]较为详细地介绍了数控玉石雕刻技术的工作流程。钟世禄[2]等对雕刻实木的加工质量优化进行了研究,得出刀具路径与进给倍率越小则雕刻质量越好的结论。

目前主流的立体雕刻机分为四轴与五轴两种,四轴即笛卡尔坐标系xyz轴,刀具可以在三个垂直的方向移动,加上旋转的刀具轴雕刻出浮雕图案。五轴则在此基础上增加一个可旋转玉石的轴,而刀具依然在xyz三个方向移动,可一次完成圆雕。李园等[3]详细展示了三轴和四轴两种雕刻机的运用,探讨了整个工作流程中刀具选择和成品之间的关系。

闵东伟[4]、普欣尧[5]、杨金林[6]、刘志[7]等认为数控玉雕技术不仅能降低玉石雕刻行业的人力成本,也能提高生产效率,紧跟市场动态发展,更能促使玉石雕刻行业从劳动密集型向着技术密集型产业发展。苏东胜[8]等探讨了在JDPaint中浮雕建模的优化和刀路设计。

基于上述研究,本文中笔者通过实验分析不同的锥形球头刀具、路径间距、速度倍率对加工单件翡翠时刀具磨损和成品质量的影响,并尝试提出合理的参数设置,为提高数控玉石雕刻效率和成品质量提供参考。

1. 材料与方法

1.1 实验材料及机器用具

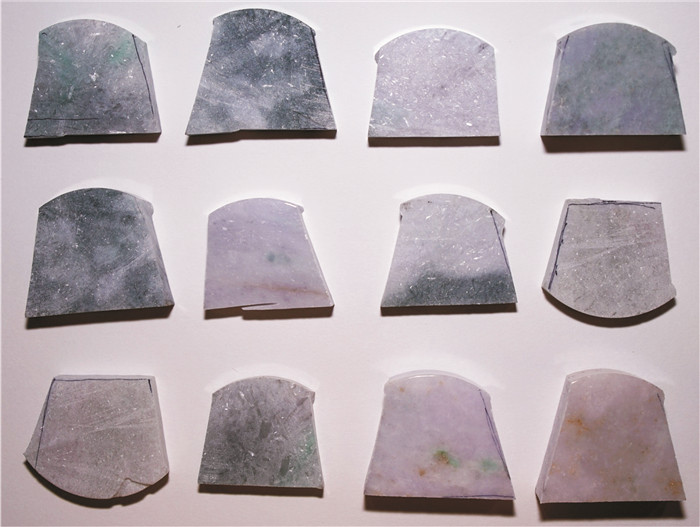

实验初期选取了数块质地相近的翡翠手镯心(图 1),按照实验设计将较厚的从中切分,较薄的直接使用,切割成了长和宽约35 mm×35 mm的12块原料,见图 1。原料的厚度有一定差异,以验证厚度对加工时间的影响。

实验机器选用玉邦YB4030P四轴雕刻机,该雕刻机与本次实验相关的主要参数有:刀头转速24 000 R/min; 吃刀深度,即z轴向加工时刀头每执行完一圈平面运动向下进深的量;速率, 也称为进给倍率,是执行刀路程序时相对于最大平面移动速度的比率,该雕刻机的最大平面移动速度为3 000 mm/min;路径间距,指在x轴方向执行完一道加工程序后下一道x轴方向程序之间y轴方向移动的间距,可任意设置,通常刀路设计时会设置该间距为球型刀头直径的10%左右;加工使用的全部刀路均使用JDPaint5.50软件进行设计,而后使用玉邦提供的专用程序转换为雕刻机可以识别的文件。

选用的加工刀具为雕刻挂件常用的直径为3.54 mm平头刀、0.6 mm和0.2 mm锥形球头刀。

1.2 实验方法

数控玉石雕刻通常采用三道工序:开轮廓,粗刀预形和细刀修形,流程图见图 2。为确保实验的一致性和相对较快获得数据,选择最为常见的机器雕刻造型坐姿弥勒佛,设置雕刻尺寸均为30×30×6 mm。

使用3.54 mm直径的平头刀开轮廓,平头刀在使用中的损耗极小,除对加工效果有影响,该刀一直使用。为保证加工过程中原料较好地黏附在底板上,所有的原料均在开轮廓后预留0.5 mm的边缘厚度。

0.6 mm的锥形球头刀开粗预形,0.2 mm的锥形球头刀精细加工,为保证实验条件的一致性,锥形球头刀每次加工均更换全新的刀具,在实验后比较刀头的磨损情况。

初期实验设计见表 1。实验中设计的3个粗刀路径间距分别为0.04 mm、0.06 mm和0.08 mm,每个路径间距做4件雕刻,速率15%和25%各2件,研究不同路径间距和速率下加工效果和刀头的磨损情况,设置同一速率2件细刀工序不同速率的加工对比,同时排除偶发情况的影响。细刀则全部路径间距为0.03 mm,对比10%和15%的速率对刀头和加工效果的影响。

表 1 实验参数Table 1. Experimental parameters序号 轮廓 粗刀 细刀 原料最大厚度/mm 吃刀深度/mm 速率/% 加工深度/mm 路径间距/mm 速率/% 路径间距/mm 速率/% 1 8.2 0.08 20 7.7 0.04 15 0.03 10 2 9.0 0.08 20 8.5 0.04 15 0.03 15 3 8.5 0.08 20 8.0 0.04 25 0.03 10 4 15.0 0.08 20 14.5 0.04 25 0.03 15 5 9.4 0.08 20 8.9 0.06 15 0.03 10 6 8.4 0.08 20 7.9 0.06 15 0.03 15 7 7.5 0.08 20 7.0 0.06 25 0.03 10 8 7.9 0.08 20 7.4 0.06 25 0.03 15 9 7.9 0.08 20 7.4 0.08 15 0.03 10 10 7.4 0.08 20 6.9 0.08 15 0.03 15 11 13.1 0.08 20 12.6 0.08 25 0.03 10 12 14.4 0.08 20 13.9 0.08 25 0.03 15 1.3 质量评价方法

对同一造型来说,雕刻过程中如不出现意外,多件成品之间的长和宽差异一般极小,造型的线条和曲面也不会有太大差异,主要的差异是完成后曲面上的刀路痕迹。该实验评价成品质量主要考量刀路痕迹的明显程度,能否通过相同的震光机抛光工序(即240号砂、800号砂及2000号砂三道工序)去除刀路痕迹后达到良好的抛光表面。

2. 结果与分析

2.1 刀头损耗的实验结果

对于锥形球头刀而言,评价其是否还能继续使用的标准是刀头平秃的程度,若导致球头的边缘直径明显大于标示的直径则无法使用。

从图 3中可看出,在完成粗刀工序后,0.6 mm锥形球头刀都有不同程度的磨损,可以看到5、6、10、12号刀头的球头相对磨耗较少。在加工完成一件30×30×6 mm的弥勒佛后,尽管有可见的金刚砂脱落、圈痕和刀头磨秃,但磨损未导致球头直径明显变大,所有刀头依然可以继续使用。

从图 4中可看出,细刀工序完成后,0.2 mm锥形球头刀在0.03 mm路径间距时,10%、15%、20%三个速率的雕刻均未明显磨损,其中6号、7号、10号和12号相对损耗要小一些。所有刀头均可以继续利用。

2.2 雕件加工的实验结果

实验发现,粗刀工序路径间距为0.04 mm和0.06 mm时,速率15%和25%完成的雕件表面质量几乎没有差异,且0.6 mm锥形球头刀的磨损情况也比较接近,最终序号1~8号按照设计的实验参数完成了加工。此后修改了9~12号原料的实验顺序和参数。

11号原料粗刀工序采用的加工参数为路径间距0.08 mm、速率35%。加工时雕刻机产生明显晃动,且加工到5%时,原料从底板脱落。而后使用纸巾搓揉成条滴502胶水,利用碳化反应加固(见图 5)。虽再次对刀,但依然有不可忽略的轮廓和粗刀工序位置偏差。粗刀工序加工到91%时,剩下的未加工部分被刀头打断掉落,使得雕件肚子上出现了一道明显的阶梯(见图 6),经过细刀工序后依然明显。细刀工序将速率提高到了20%,未见与10%和15%的速率的效果有明显区别。

12号原料粗刀加工依然使用路径间距0.08 mm,速率25%,雕刻机无明显的振动,顺利完成了雕刻。

9号和10号原料加工粗刀工序使用了0.10 mm的路径间距,速率为25%,粗刀工序完成后雕件表面的刀路痕迹很明显,此后细刀工序9号先使用20%的速率发现未能很好去除粗刀工序的刀路痕迹,10号原料细刀工序使用10%的速率也没有去除。

最后增加13号原料,粗刀工序使用0.10 mm的路径间距,速率25%,但是增加了0.03 mm的加工余量,随后细刀工序速率20%,完成后粗刀工序刀路痕迹被去除。13号原料粗刀工序1%时原料脱落,脱落后可看到背面确实完全覆盖了胶水,见图 7,不存在固定工序上的失误。而后同样利用502胶水和纸巾条加固,虽再次对刀,但依然有不可忽略的轮廓和粗刀工序位置偏差。

从图 8中可以看到随着路径间距的不断增加,在雕件表面的粗刀刀路痕迹依次加深而明显。

从图 9中可见,1-12号以及13号雕件的眉眼线条细节均很好,表面可见细小的刀路痕迹,而9号和10号雕件眉眼线条也很好,但表面有非常明显且宽的刀路痕迹。

轮廓、粗刀和细刀工序耗时具体结果见(表 2)显示,对于粗刀工序和细刀工序,同一路径间距和速率的耗时是基本相同的。

表 2 加工工序与耗时的实验结果Table 2. Experimental result of carving process and time consumption序号 轮廓 粗刀 细刀 加工深度/mm 耗时/s 路径间距/mm 速率/% 耗时/s 路径间距/mm 速率/% 耗时/s 1 7.7 1 103 0.04 15 4 227 0.03 10 7 500 2 8.5 1 213 0.04 15 4 227 0.03 15 5 603 3 8.0 1 134 0.04 25 3 044 0.03 10 7 505 4 14.5 2 043 0.04 25 3 044 0.03 15 5 607 5 8.9 1 246 0.06 15 2 832 0.03 10 7 503 6 7.9 1 124 0.06 15 2 838 0.03 15 5 603 7 7.0 1 000 0.06 25 2 037 0.03 10 7 503 8 7.4 1 056 0.06 25 2 044 0.03 15 5 606 11 12.6 1 783 0.08 35 1 271 0.03 20 4 663 12 13.9 1 962 0.08 25 1 542 0.03 15 5 608 9 7.4 1 057 0.10 25 1 254 0.03 20 4 664 10 6.9 981 0.10 25 1 255 0.03 10 7 504 13 8.2 1 169 0.10 25 1 223 0.03 20 4 560 2.3 刀头损耗结果分析

加工单件简单的翡翠雕件,对于0.6 mm的锥形球头刀,路径间距在0.04~0.10 mm之间,速率为15%~35%的磨损程度有差异,但该差异与实验设置的路径间距和速率没有相关关系,也与刀头的加工深度没有相关关系,由于实验的雕刻难度不大,次数不足够多,同时为保证安全,未能测试到刀头的极限情况,故仅能推测磨损差异与刀具制造工艺及质量等有关。

细刀工序使用的0.2 mm锥形球头刀情况类似,磨损程度并不相同,但也与实验设置的路径间距和速率没有相关关系。

2.4 加工耗时分析

从图 10中可以看出,轮廓工序中的耗时与加工深度是明显正相关的,随着加工深度越大,耗时就越长,耗时(s)=142.27×加工深度(mm)。

从图 11中可见对于不同的路径间距,提高速率都能缩短加工的耗时,速率25%相比15%的速率,在路径间距0.04 mm时,时间缩短了28%,路径间距0.06 mm时缩短了27.9%。35%速率相比25%的速率,在路径间距同为0.08 mm时,时间缩短了17.6%。

从路径间距的角度看,速率15%时,0.06 mm比0.04 mm耗时缩短了32.9%。速率25%时,0.06 mm比0.04 mm耗时缩短了33%,0.08 mm比0.06 mm耗时缩短24.4%,0.10 mm比0.08 mm耗时缩短18.6%

从图 12中可以看出,细刀工序的耗时表现为斜率减小的斜线,速率15%比10%的耗时减少25.3%,速率20%比15%的耗时减少16.8%。

结合粗刀工序和细刀工序的耗时情况,可以推测对于锥形球头刀,路径间距增大耗时必然减少,速率提高必然耗时减少。减少的幅度随着路径间距和速率的增加都越来越少。

2.5 雕刻质量分析

细刀工序完成后的雕件表面情况见图 9,虽然进行实验的翡翠质地较粗,但雕件的线面细节都完整保留,仅有一件弥勒佛的手部崩口缺失,其余均完整保留。

实验中粗刀工序0.6 mm锥形球头刀的在路径间距0.04 mm到0.08 mm之间所产生的刀路痕迹,均可被细刀工序0.2 mm锥形球头刀的路径间距0.03 mm加工消除,留下细刀工序的极轻微,正常抛光可去除的刀路痕迹。而粗刀工序使用路径间距0.10 mm产生的刀路痕迹则无法消除,可通过在粗刀工序刀路设计中增加0.03 mm的加工余量,再对细刀工序后得到的刀路痕迹正常抛光去除。

使用震光机抛光后进行观察,见图 13,粗刀工序路径间距0.10 mm的完成品在表面凹陷处,如弥勒佛的脸颊部分,依然有明显的刀路痕迹,需要手工抛光进行处理。在线条紧密位置,如眼睛处,放大观察可见线条边缘相连,失去细节。相比之下粗刀工序路径间距0.04 mm到0.08 mm之间的则无上述瑕疵。

3. 讨论

3.1 原料脱落

实验中路径间距为0.04 mm和0.06 mm的8组实验均未出现原料脱落的情况,而路径间距为0.08 mm和0.10 mm的5组中就有两组发生了脱落,导致成品发生了难以弥补的错误,造成原料的浪费。

从雕刻机本身而言,设置的参数并没有达到极限,但从成品率角度来看,对于翡翠这种坚硬的材料,过高的路径间距和速度会导致原料脱落概率的上升,非常影响成品率。现实生产中,往往是一个工人照看多台雕刻机,一旦原料发生脱落,可能不会被及时发现,并停止雕刻机,从而导致错误的雕刻或者原料破损等,造成难以弥补的损失。

根据实验结果,粗刀工序较为理想的最大路径间距为0.08 mm,最大速率为25%;且在此基础上再提高路径间距和速率获得的耗时减少幅度越来越少。若确实需要通过提高路径间距和速率来提高加工效率,应在加工前使用纸巾条和502胶水固定原料。

3.2 刀具损耗

粗刀工序中路径间距0.08 mm、速率25%,所需加工时间是路径间距0.04 mm、速率15%所需时间的36.5%,缩短了一半还多;细刀工序中速率20%所需时间为速率10%的62.2%,但刀具的磨损情况并无较大差异。所以对于单件的简单雕件,在不计刀具成本的情况下,可尽量增大路径间距和速率来提高加工效率。

在本例中,刀具损耗没有产生明显的规侓性差异,可忽略不计。刀具磨损到何种程度会影响加工质量则需要进一步增加实验进行验证。

3.3 加工质量

雕件加工的表面质量包括点线面的细节和刀路痕迹的明显程度,从实验中可看出,加工质量与细刀工序的锥形球头刀直径和路径间距关系最大,细刀工序直至20%的速率。加工质量也并没有下降。

粗刀工序的路径间距过大,在本例中为0.10 mm时,确实会产生无法通过振光机抛光去除的刀路痕迹,甚至线条细节也会模糊。若在粗刀工序增加加工余量即可通过细刀工序将刀路痕迹去除,且不增加加工的时长。否则需要增加人工处理环节进行修饰,不仅增加耗时,也提高了人力成本。

3.4 效率

事实上,按照当前实验所得的最快安全加工参数,即轮廓工序3.54 mm平头刀,吃刀深度0.08 mm,速率20%;粗刀工序0.6 mm锥形球头刀,路径间距0.08 mm,速率25%;细刀工序0.2 mm锥形球头刀,路径间距0.03 mm,速率20%,完成一件30×30×6 mm弥勒佛的雕刻机运作时间共计7 102 s,即1小时58分22秒,加上开料、刀路设计、粘料、对刀、换刀、取件等人工操作时间约20分钟,需要2小时20分钟左右。而熟练的弥勒佛手工雕刻工匠在1小时内就可完成,单台雕刻机的效率并不比单个雕刻工匠高。

然而,批量生产同种雕件时,一台电脑数控雕刻机可以在加工平台上放置几十件材料进行连续加工,并且雕刻机的所有步骤基本都是重复的,可以由一个工匠操作多台机器,因此在单位时间内的生产效率则远超人工雕刻,且正确设置和操作的情况下容错率高。在批量生产前可先完成少量雕件,统计不同工序的耗时,最大限度利用人工操作时间,提高效率。

4. 结论

本文使用玉邦YB3040P四轴雕刻机在既定参数下雕刻了13个翡翠弥勒佛,分析了刀具的磨损、成品的表面质量和耗时,得到以下结论。

(1) 使用平头刀开轮廓时,速率一致的情况下,加工的耗时与加工的深度正相关,耗时(s)=142.27×加工深度(mm)。

(2) 使用锥形球头刀时,耗时和路径间距及速率均有关系,耗时减少的幅度随着路径间距和速率的增加都越来越少。

(3) 对于翡翠而言,粗刀工序采用0.6 mm锥形球头刀时,安全的最大路径间距为0.08 mm,速率为25%。

(4) 翡翠数控雕刻的表面质量主要与细刀工序的锥形球头刀刀头直径和路径间距有关,与速率大小无关。若粗刀工序路径间距较大,在本例中路径间距为0.10 mm时,直接抛光会残留明显的刀路痕迹,应通过增加粗刀工序加工余量, 让细刀工序去除刀路痕迹。

-

表 1 实验参数

Table 1 Experimental parameters

序号 轮廓 粗刀 细刀 原料最大厚度/mm 吃刀深度/mm 速率/% 加工深度/mm 路径间距/mm 速率/% 路径间距/mm 速率/% 1 8.2 0.08 20 7.7 0.04 15 0.03 10 2 9.0 0.08 20 8.5 0.04 15 0.03 15 3 8.5 0.08 20 8.0 0.04 25 0.03 10 4 15.0 0.08 20 14.5 0.04 25 0.03 15 5 9.4 0.08 20 8.9 0.06 15 0.03 10 6 8.4 0.08 20 7.9 0.06 15 0.03 15 7 7.5 0.08 20 7.0 0.06 25 0.03 10 8 7.9 0.08 20 7.4 0.06 25 0.03 15 9 7.9 0.08 20 7.4 0.08 15 0.03 10 10 7.4 0.08 20 6.9 0.08 15 0.03 15 11 13.1 0.08 20 12.6 0.08 25 0.03 10 12 14.4 0.08 20 13.9 0.08 25 0.03 15 表 2 加工工序与耗时的实验结果

Table 2 Experimental result of carving process and time consumption

序号 轮廓 粗刀 细刀 加工深度/mm 耗时/s 路径间距/mm 速率/% 耗时/s 路径间距/mm 速率/% 耗时/s 1 7.7 1 103 0.04 15 4 227 0.03 10 7 500 2 8.5 1 213 0.04 15 4 227 0.03 15 5 603 3 8.0 1 134 0.04 25 3 044 0.03 10 7 505 4 14.5 2 043 0.04 25 3 044 0.03 15 5 607 5 8.9 1 246 0.06 15 2 832 0.03 10 7 503 6 7.9 1 124 0.06 15 2 838 0.03 15 5 603 7 7.0 1 000 0.06 25 2 037 0.03 10 7 503 8 7.4 1 056 0.06 25 2 044 0.03 15 5 606 11 12.6 1 783 0.08 35 1 271 0.03 20 4 663 12 13.9 1 962 0.08 25 1 542 0.03 15 5 608 9 7.4 1 057 0.10 25 1 254 0.03 20 4 664 10 6.9 981 0.10 25 1 255 0.03 10 7 504 13 8.2 1 169 0.10 25 1 223 0.03 20 4 560 -

[1] 李敏芳. 数控技术在玉雕中的应用研究[J]. 职业技术, 2015, 14(12): 90-92. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYJU201512036.htm Li M F. Study on the application of NC technology in the jade carving[J]. Vocational Technology, 2015, 14(12): 90-92. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZYJU201512036.htm

[2] 钟世禄, 黄淳, 张宏玉, 等. 实木数控雕刻加工质量优化研究[J]. 林业工程学报, 2016, 1(6): 142-147. https://www.cnki.com.cn/Article/CJFDTOTAL-LKKF201606031.htm Zhong S L, Huang C, Zhang H Y, et al. Research on processing quality optimization of solid wood CNC carving[J]. Journal of Forestry Engineering, 2016, 1(6): 142-147. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LKKF201606031.htm

[3] 李园, 文海. 立体数控雕刻技术在玉雕中的实践应用[J]. 美与时代(上), 2017(2): 40-42. https://www.cnki.com.cn/Article/CJFDTOTAL-MYSS201702015.htm Li Y, Wen H. Practice and application of NC carving technology in jade carving[J]. Beauty and Times(I), 2017(2): 40-42. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MYSS201702015.htm

[4] 闵东伟. 电脑数控雕刻在玉雕加工行业的运用[J]. 神州, 2019(30): 249. Min D W. Application of CNC carving in jade carving industry[J]. Divineland, 2019(30): 249. (in Chinese)

[5] 普欣尧. 立体数控雕刻技术在玉雕中的实践应用[J]. 居舍, 2019(9): 59. https://www.cnki.com.cn/Article/CJFDTOTAL-JUSH201909057.htm Pu X Y. Practice and application of NC carving technology in jade carving[J]. Home, 2019(9): 59. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JUSH201909057.htm

[6] 杨金林. 立体数控雕刻技术在玉雕中的实践应用[J]. 天工, 2021(5): 110-111. https://www.cnki.com.cn/Article/CJFDTOTAL-TGTG202105049.htm Yang J L. Practice and application of NC carving technology in jade carving[J]. Masterpieces of Nature, 2021(5): 110-111. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TGTG202105049.htm

[7] 刘志. 数控技术在玉雕中的应用研究[J]. 天工, 2021(8): 84-85. https://www.cnki.com.cn/Article/CJFDTOTAL-TGTG202108030.htm Liu Z. Research on the application of NC technology in jade carving[J]. Masterpieces of Nature, 2021(8): 84-85. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TGTG202108030.htm

[8] 苏冬胜, 陈龙海. 基于JDPaint的浮雕建模数控雕刻技术应用研究[J]. 现代制造技术与装备, 2021, 57(3): 79-80. https://www.cnki.com.cn/Article/CJFDTOTAL-SDJI202103030.htm Su D S, Chen L H. Application research of relief modeling and NC carving technology based on JDPaint[J]. Modern Manufacturing Technology and Equipment, 2021, 57(3): 79-80. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SDJI202103030.htm

[9] 麦启明, 张建强. 数控雕刻机路径优化技术研究[J]. 机床与液压, 2021, 49(16): 60-66. https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY202116014.htm Mai Q M, Zhang J Q. Research on path optimization technology for CNC engraving machine[J]. Machine Tool & Hydraulics, 2021, 49(16): 60-66. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY202116014.htm

下载:

下载: